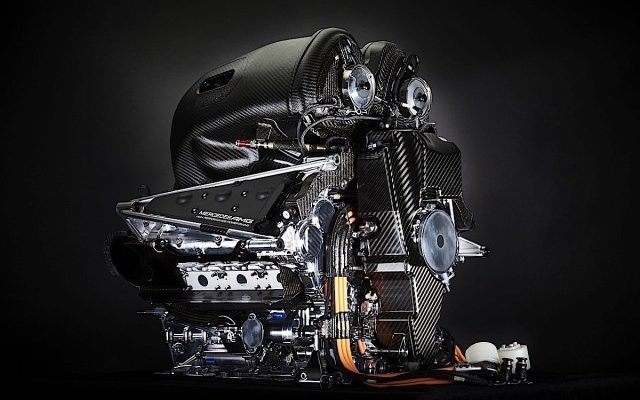

TJI is the hottest buzzword on the F1 circuit right now.Numerous medias reported that Mercedes has been utilizing a form of this technology since the turbo V6 era arrived.Ferrari then adapted the technology last year,and thoughts are that Renault will join the party shortly.

Improving combustion efficiency is key for F1 engineers since the regulations limit the total amount of fuel that can be used in a race as well as the fuel-flow rate. This new technology replaces the standard spark plug in each cylinder with a jet ignition chamber,and helps support ultra lean-burn operation in gas engines.

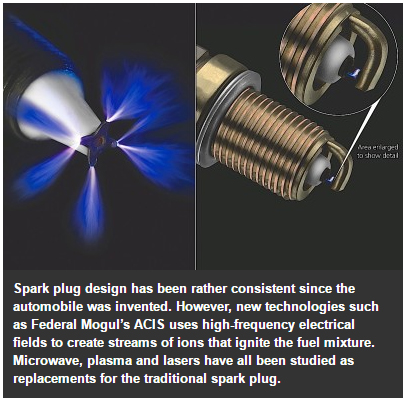

If properly designed, this jet igniter can be a drop-in replacement for the spark plug.It’s basically the most advanced evolution of ignition,since the basic spark plug was invented over a century ago. There have been plenty of alternative spark technologies proposed over the past few decades by engineers, including using microwave, plasma and even lasers to ignite the air-fuel mixture in an internal combustion engine (ICE). But Formula 1 doesn’t allow any type of high-frequency ignition, and automakers have yet to find an alternative that’s as cost-effective as the traditional spark plug.Observes thought that F1 engine builders have solved all the problems with the HCCI,or at least were using a type of HCCI with spark ignition.

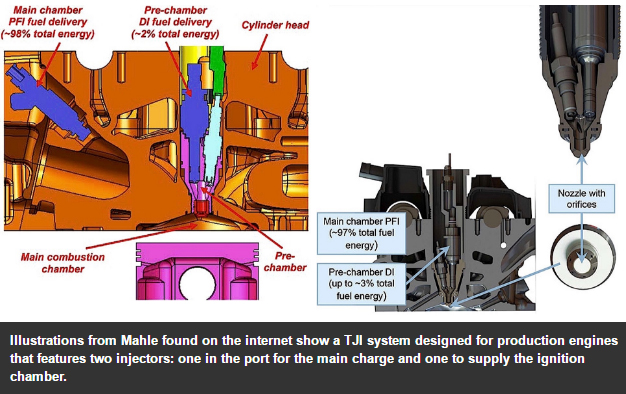

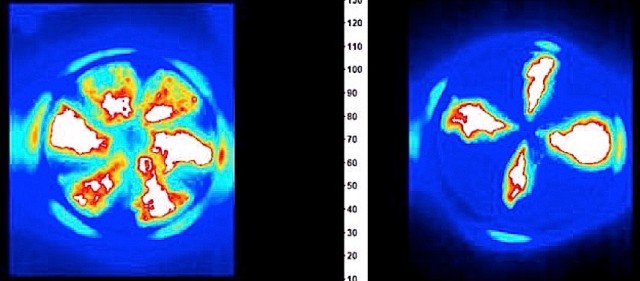

HCCI is the best combustion for the ICE because it theoretically has the best of both worlds spark and compression engine. An HCCI engine draws an air-fuel mixture into the cylinder,similar to a gas spark engine, then ignites the mixture using compression,similar to a diesel engine. There is no spark or fuel-delivery timing,but there’s a much lower temperature combustion. That means lower NOx emissions and higher heat efficiency,which cuts down on CO2 emissions. The only problem is that there are no timing controls.Ignition can only go as far as the laws of chemistry and physics,so high-speed and high-load conditions where cylinder temperatures rise can be a quite unpredictable. As we said earlier,TJI replaces the spark plug with a jet ignition chamber. During the compression stroke,around 97 percent of the fuel charge is injected directly into the cylinder and the remaining three percent of fuel is directed into the chamber where a traditional spark plug ignites that small charge within the tiny confines of the chamber.The jet stream of hot gasses are forced through a number of tiny holes in the chamber,and into the main cylinder to ignite the rest of the air-fuel charge,which is by now thoroughly mixed and lean. According to Mahle, these hot jets fire out to the edge of the piston to ignite the mixture. From a Mahle annual report:

“While ignition normally takes place in the center of the cylinder, with Mahle Jet Ignition it essentially takes place from the outside toward the inside. This allows significantly better combustion of the fuel mixture. The result: more power with considerably less residue.”

When TJI hype broke out,almost every publication used illustrations from the Mahle reports,but the equipment depicted was for a production engine that utilized two injectors per cylinder: one for the main air-fuel charge and a secondary injector just for the ignition chamber. However,Formula 1 allows only a single injector per cylinder,so team engineers had to design a unique combustion chamber with a pre-ignition chamber that supports the spark plug tha can still draw that 3 percent of fuel from the injector. The final effect is still the same with flame jets coming out of the small chamber and igniting the compressed air-fuel mixture at several points simultaneously in the cylinder.