The Swedish manufacturer seeks to eliminate Turbo Lag, developing anti-lag technology that doesn’t depend on burning fuel in the piping before the turbine, or messing with valve timing for a “misfiring system”

Volvo’s approach to the problem of turbo lag is quite clever, and if applied properly, it could improve fuel economy as well as engine response.

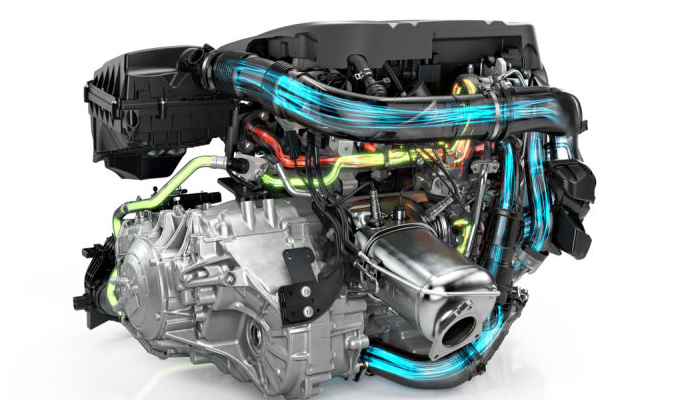

Basically, a compressed air tank feeds a nozzle that injects high pressure air into the turbine exhaust gas inlet, making the turbo spool up much quicker when accelerating rapidly, making for a much more linear and direct response. The air tank is automatically filled by an electric compressor fitted in the engine bay.

This solution seems to be a cleaner and more efficient way of improving performance without compromising fuel economy. Volvo is currently applying this development to their Turbo Diesel models.